The word “LASER” is an acronym for Light Amplification by Stimulated Emission of Radiation and has been around since the 1960s. It was a significant breakthrough in manufacturing, medicine, and other similar industries.

Amongst multiple similar processes prevalent around the technology, the most common use case is laser cutting. It offers manufacturers an ability to cut through metals and alloys with a high degree of accuracy. It boasts a market of USD 3360 million in 2020. With an expected CAGR of 9.7 percent, we expect it to topple USD 5880 million by 2024.

In today’s article, we discuss things you need to know about laser cutting and why it has been such a rage.

Table of Contents

What is the laser cutting process?

In layman’s terms, laser cutting refers to a thermal process where a focused laser beam melts materials. Here, a CNC control is used to move the laser beam and get the desired shape. A coaxial gas jet then ejects the molten material and creates a kerf.

In technical terms, the laser beam is a column of very high-intensity light pertaining to a single color or wavelength. It travels through the laser resonator through the assigned path and flows through the machine’s nozzle alongside a compressed gas, typically nitrogen or oxygen.

For focusing, the machine uses a unique lens, or a curved mirror, and it aims at the spot to create extreme heat. It results in rapid melting, and sometimes partial vaporization of the molten metal.

There are three varieties of laser cutting –

- Flame cutting – Here oxygen plays an assisting role, which creates an exothermic reaction making it more potent.

- Fusion cutting – Here nitrogen or any of the other inept gases assist the laser in expelling the liquid metal out of the kerf.

- Remote cutting – Here, there are no gases for assisting, but it uses a high-intensity laser beam which compensates for the same. Instead of manual handling, offline CAD/CAM systems with a three-axis flatbed mechanism or six-axis robots handle the process.

What is the difference between CNC cutting and laser cutting?

CNC stands for Computer Numeric Control devices which are a set of specialized tools for efficient and accurate cutting.

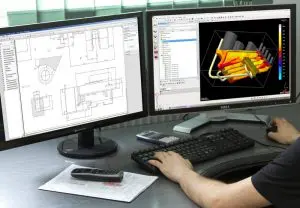

It employs an expert who creates a CAD diagram of the shape he/she requires. Once the design is finalized, we place the material to be cut on the cutting surface. The computer processes a signal to the CNC machine, which then moves along the axes to give life to the design.

In laser cutting, a CNC machine controls the laser metal-cutting machine, which is the same as in CNC cutting.

However, it employs heat instead of a cutter to get the precise design. It ensures high precision and clean edges, which improves the appearance and functionality of the product it creates. Also, it can achieve cuts as low as 0.1mm with ease, making it a versatile option.

Types of laser cutting used for sheet metal

Here are the laser cutting variants that the sheet metal fabrication industry regularly employs –

CO2 (carbon dioxide) laser

In this method, an electric discharge helps in pumping the laser. The CO2 laser employs a mix of carbon dioxide, helium, and nitrogen in gas form. These have an efficiency of 10 percent, which is higher than lamp-pumped, solid-state lasers, but cannot compete with most others well.

These typically emit at a wavelength of 10.6μm and can generate ample power for cutting. It employs three-axis systems with two for dimensional positioning control and one for managing height.

Fibre lasers

A type of solid-state laser, fibre lasers generate beams using a tangible medium, mostly a series of laser diodes. It has an optical fibre to transmit the ray once it amplifies.

It is adjusted parallel to the target, and a lens then directs it to the material that will be cut.

It doesn’t have any moving parts or mirrors, which makes its maintenance more straightforward and cheaper. These also offer far higher energy efficiency (up to 30 percent) than CO2 lasers and are perfect for cutting copper, aluminum, and brass seamlessly.

Direct diode lasers

These are amongst the newest innovations in the world of laser cutting. Here, the direct diode laser uses a beam-combining technique to generate better results. In this process, a host of diodes develop lasers of varying wavelengths which are directed to the material surface.

There is no brightness-enhancing stage in between, like in fibre laser ensuring higher wall-plug efficiency and lower optical loss. But their inability to optimize their focus means that their output falls short to that of fibre lasers.

How does laser cutting work?

A laser beam is typically a column of a beam that is about ¾ of an inch. It is invisible to human eyes and travels through the resonator and can bounce in different directions because of beam-benders.

These are then focused through the plate and pass the nozzle to hit the surface, which is to be cut.

Here are some significant methods that manufacturers use –

-

Vaporization cutting

In vaporization cutting, the beam creates a keyhole in the surface of the material. The continuous focus leads to higher absorptivity and deepens the hole.

The high temperature is apt for usage on non-melting material such as wood, plastic, and others.

-

Melt and blow

Melt and blow, also known as fusion cutting, uses high-pressure gas to melt the metal and blow it from the cutting area.

Here, the material is first heated up to the melting point, and a gas jet then removes it out of the kerf, ensuring usage of limited energy to achieve the final shape.

-

Stealth dicing

Stealth dicing operated with a pulsed Nd: YAG laser is the process of separation of microelectronic chops from silicon wafers.

It is prepared in a semiconductor device fabrication and has an apt wavelength for managing silicon gaps.

-

Thermal stress cracking

Glass and other brittle materials are prone to micro-cracks developing during the process of cutting.

For preventing thermal fracture, a beam is focused on the surface, achieving expansion and localized heating. It develops mini cracks which can be guided by adjusting the flow of the beam.

Applications of laser cutting

Laser cutting has found its application in a wide array of manufacturing industries. The use cases include cutting and scribing metals and softer materials. Here are the major industries that use it –

-

Automotive

Automotive industries manufacture hundreds of homogeneous parts every single day. Here, laser cutting finds use in cutting metals and other materials for forming the body of the vehicles, which include interiors as well as exterior parts.

-

Die, molds, and tools manufacturing

Laser cutting is known for achieving a high degree of precision, which is a must have for the die, molds, and tools industry. Its ability to create unlimited pieces with exact dimensions and lower wastage makes it a cost and time-efficient adoption for this field.

-

Silicon manufacturing

Silicon is a soft, high-temperature tolerant, age-resistant material which is highly flexible. Laser cutting allows manufacturers to produce smaller silicon parts with an excellent finish that is usually not available with other modes of cutting.

-

Ceramic manufacturing

Ceramic is a beautiful but brittle material which requires a lot of care while handling. With laser cutting, manufacturers can achieve lower processing time with an excellent finish. Ceramic finds use in a lot of industries which include jet engines, smartphones, cooktops, and others.

-

Medical instruments manufacturing

The induction of laser cutting has allowed surgeons to make precise cuts which are known to heal faster too. Laser surgery is known and respected around the globe for performing numerous types of surgeries. Also, laser cutting helps create intricate medical devices such as bone reamers, valve framers, and others.

-

Jewellery

It is easy for laser cutting to find use in the jewellery industry. Its affinity to thin sheets, high precision, flexibility, and speed makes it a perfect addition. Also, its ability to etch further enhances the proposition.

Advantages and disadvantages of laser cutting

Here are the advantages that laser cutting offers –

- It ensures precise cutting with a high level of accuracy

- It provides reduced contamination and more comfortable work holding

- It can penetrate dense materials with ease

- Machine-directed laser cutting aids in lower wastage and limited energy use

- Laser cutting offers tremendous flexibility with varying levels of automation and excellent finishing

Here are the side-effects of laser cutting –

- It requires a high level of expertise

- It is not suitable for metals with thickness exceeding 20mm

- These machines are costlier than many other methods available for such purposes

- Heating specific materials can lead to the release of dangerous fumes, harmful for the environment

Laser cutting is the future

Effective laser cutting is dependent on many factors which include the type of laser, subject material, thickness, and others. An efficient cut requires minimum power and high speed to maintain high accuracy.

It is why most cutting heads house a capacitive sensor with an additional axis for managing the distance of the head from the part surface. The ability to control the cutting process with the help of software further enhances the results of laser cutting while reducing costs. There are several factors which affect the cut, but if you handle them well, it is a stable process with minimal distortions.