As one of the most abundant metal elements on the planet, Aluminium with its unique physical properties, makes it one of the most widely used metals in many industries. This is due to the fact that Aluminium is light in weight, is highly durable, possesses a high strength-to-weight ratio, and is resistant to corrosion.

In addition, Aluminium can be easily fabricated into the desired shape, it can also be joined by welding or adhesive bonding, and can be anodised and painted to offer a wide range of attractive finishes. Aluminium is also a good conductor of heat as well as electricity. Most importantly, at the end of its lifespan, Aluminium can be recycled and reused.

But what exactly is Aluminium, and why is it so important? Let our die casting parts manufacturer experts explain.

Table of Contents

What is ‘Pure’ Aluminium?

The likelihood of finding pure Aluminium is close to impossible, this is because Aluminium is very reactive in its purest state, and thus it can never be found as a pure metal. The main source of commercially manufactured Aluminium is known as Bauxite, a reddish-brown clay-like deposit containing minerals such as iron, silicates, and Aluminium Oxide.

To get Aluminium, Bauxite must first be purified to yield a white powder – Aluminium Oxide. Aluminium is then extracted from Aluminium Oxide via electrolysis. In its purest state, Aluminium as an element is too soft and malleable to be used commercially, which is why Aluminium is usually found as an alloy. By creating an Aluminium alloy through the combination with other metals such as copper, magnesium, tin, or zinc, the overall strength of the metal is enhanced.

What is Recycled Aluminium

Recycled or secondary Aluminium is extracted from various waste streams as scrap. It is then segregated as per its chemical makeup, with purer forms of recycled Aluminium commanding the highest in value and Aluminium containing other alloys having the lowest. As Aluminium is non-ferrous in nature, impurities from scrap are removed using magnets. To purify the molten metal, the leftover Aluminium is then stripped of any existing surface treatments and melted down. The end product is an Aluminium alloy that possesses the properties of pure Aluminium.

Pure Versus Recycled Aluminium

As mentioned earlier, Aluminium can be recycled and reused, thus making it a highly favoured metal used by many industries. In fact, Aluminium is 100 percent recyclable, and 75 percent of all Aluminium that has ever been produced is still in use today. As compared to pure Aluminium which is energy intensive to produce, recycled Aluminium is a more environmentally friendly process, why is that so? Consider this:

- The production of Recycled Aluminium uses 95 percent less energy as compared to the primary production process of extracting Aluminium from Bauxite.

- It also reduces greenhouse gas emissions produced in the primary production process by close to 97 percent.

- Recycling a tonne of Aluminium saves nine tonnes of carbon emissions and four tonnes of Bauxite.

Essentially, the benefits of using recycled Aluminium is an environmentally friendly decision to make as it helps reduce energy consumption, reduce mining and shipping pollution, as well as reduce carbon emissions. All of these are attained without having to compromise quality or durability of the metal.

Choose EKO for Your Aluminium Die Casting Needs

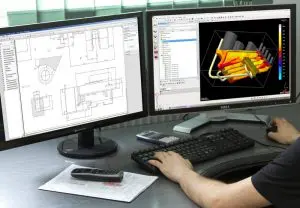

With over 20 years of Aluminium die casting expertise, EKO Industries’ team of experienced engineers will evaluate your requirements to help you decide what is best for your company’s needs. And because most products can be manufactured using secondary Aluminium, while maintaining the properties and characteristics of primary Aluminium, recycled Aluminium can be the solution for your next product. Speak to us today to find out more about our precision die casting design process and how it can benefit your business.