Cold Chamber Die Casting

Cold Chamber Pressure Die Casting

When it comes to manufacturing precise and accurate castings, precision die casting is one of the most efficient ways to ensure a consistent and high-quality end result. Cold chamber pressure die casting is a form of precision die casting that is preferred when working with metals that have a high melting point, including copper, brass, and aluminum.

The process helps to create stronger parts than those made out of plastic injection moldings with the same directions, ensuring durability and strength in your equipment. Cold chamber die casting is also known for producing stronger and denser metal casings that are suitable for long-lasting use such as for the automotive industry.

How Cold Chamber Die Casting Works

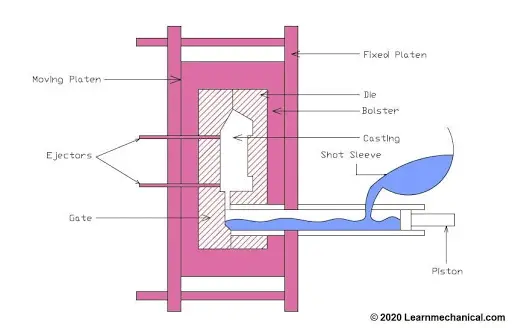

Cold chamber die casting is a process where metal is injected into a cold chamber, or cylinder, that is attached to the injection system of a die casting machine. The first step in the cold chamber die casting process is to heat the metal to its melting point. The melted metal is then poured into a cold chamber, where it is injected into the mold under high pressure. Once the metal has cooled and solidified, the part is ejected from the mold.

Cold chamber die casting can be a complex process, and only the best materials will be able to withstand the high temperatures and pressures involved. If you are looking to produce parts with tight tolerances and smooth finishes, be sure to get a quote from EKO.

With a proven track record in delivering high-quality products in USA and Malaysia, rest assured that you are partnering with a die casting company that has the experience and expertise to meet your specific needs. Reach out to us for more information today.

Frequently Asked Questions About Cold Chamber Pressure Die Casting

In hot chamber die casting, the injection mechanism’s cylinder chamber is completely immersed in the molten metal. This direct immersion into the metal enables a fast, convenient mould injection process that leads to higher production rates. In comparison, during cold chamber pressure die casting, the metal is heated separately in a furnace outside the machine before being fed into the casting chamber and being pressure cast into the mould.

The process is a little slower compared to hot chamber die casting, as new material must be brought in from an external furnace at the start of each production cycle. The cold chamber process also requires much more pressure applied in order to fill the cold chamber with the right amount of molten metal.

While there are some disadvantages compared to hot chamber die casting, the main advantage of cold chamber die casting is that the machinery stays cooler and can thus handle metals at a much higher melting point. This makes it suitable for die casting metals including zinc, aluminum, brass, and copper. Cold chamber process castings also have superior mechanical properties, with a smooth finish and thin falls. Both hot and cold chamber die casting are suitable for manufacturing precise castings depending on your specific industrial needs. Get in touch with us for more information.

The method of cold chamber die casting is mostly preferred for metals that have very high melting points. This includes metals such as copper, brass, and aluminum.

As the furnace is not attached to the machine, it will require an outside furnace and a ladle to pour the molten metal.

The cold chamber die-casting process is quite known for its ability to produce denser metal casings.

The process

In this process, the metal is heated to a molten state in a furnace located outside the machine.

The liquid metal is then transported to the casting machine and fed into the machine’s chamber.

Source: Learn Mechanical

The machine uses a plunger, which forces the liquid metal into the cavity of the mold.

The pressure usually ranges from 2,000 and 20,000 psi.

The separate heating process differentiates the cold chamber die casting process from the hot chamber one.

The molten metal is transferred either manually or automatically by the ladle to the shot sleeve. The injection piston forces metal into the die.

As this is a single-shot operation, this process helps minimize contact between the injector components and hot metal. This helps to further enhance the operating life and efficiency of the machine components.

With this process, it is possible to lower the melting point of alloys.

The process of cold chamber die casting is ideal for metals with corrosive properties or high melting points.

Advantages of Cold Chamber Die Casting

1. Long-lasting and robust components

Cold chamber die casting helps to create parts that are strong and long-lasting. The components manufactured out of this process are robust and improve the visual appeal of the surrounding area.

2. Cost-effective process

This process is highly effective and saves many costs, helping to create a broad range of components compared to other manufacturing methods.

3. Increased strength

Cold chamber die casting helps to create stronger parts than those made out of plastic injection moldings having the exact dimensions.

4. Easy to assemble

This process helps to create fastening elements such as studs and bosses. Holes can be carved, and external threads can be cast.

5. Accurate in dimension

Using this process, machine parts can be created: heat resistant, dimensionally stable, and having a high level of tolerance.

6. Better finished products

The process of cold chamber die casting helps to produce smooth parts having a high level of finish. The products can easily be plated and finished by menial effort.

Difference between the Cold Chamber and Hot Chamber process

The primary difference between a cold chamber and hot chamber die casting is that in the latter, the source of molten metal is attached to the machine in a hot chamber process. In contrast, in a cold chamber die casting process, liquid metal is introduced into the chamber from an external source.

In the cold chamber process, as the molten metal is brought from an external source, the die casting machinery will stay cooler and handle metals with a high melting point.

Industrial manufacturing of metals with a high melting point such as zinc, aluminum, brass, and copper is usually done with a cold chamber die casting process.

One slight disadvantage of the cold chamber process is that the manufacturing process is a bit slow compared to the others as the material must be brought in for every production cycle.

On the other hand, in a hot chamber manufacturing process, there will be a constant output.

The cold chamber process requires more pressure than that of the hot process. For the cold die casting, pressures of 3000psi to 50000psi (20MPa to 350MPa) are needed to fill the cold chamber with the molten metal in the right amount.

The cold chamber process creates better castings with superior mechanical properties. The castings that are produced have a smooth finish with thin falls.

The article is a part of our comprehensive series on “Die casting: Process, Equipment, Uses, and More”.