Hot Chamber Die Casting

Hot Chamber Die Casting

Hot chamber die casting is a technique that utilizes alloys with low melting temperatures like zinc and magnesium to manufacture high-precision die cast products. The hot chamber process cannot accommodate alloys with high melting temperatures, as it will result in damage to the gooseneck, nozzle, and other components of the casting machine.

The Hot Chamber Die Casting Process

Your Trusted Hot Chamber Die Casting Partner

EKO Industries is your reliable business partner for hot chamber die casting. Our design engineers work closely with you to ensure that the chosen designs will be a success in mass production. We provide you with hot chamber die casting products based on your specific requirement in a timely manner. We are well versed in handling a wide variety of materials and are experienced in producing parts specific to numerous industries.

At EKO, we believe quality control is essential to building a successful business that delivers products to meet and exceed customer expectations. Through thorough inspection and control over our die casting supplier production processes, we ensure that defects are kept to an absolute minimum. EKO continues to provide high value, quality parts and services and maintain standard excellence. Contact our team to find out more about how you can leverage hot chamber die casting today!

Frequently Asked Questions About Hot Chamber Die Casting

The hot chamber die casting process offers plenty of advantages. These include:

- Reduced porosity

- Faster cycling production

- Longer life of the machinery as it only handles metals with low melting points

- More efficient process

- Lesser metal wastage

It all boils down to the material you are working with. Cold chamber die casting works well for metals with high melting points, such as aluminum and copper. On the other hand, hot chamber die casting only works for metals with lower melting points such as magnesium, zinc, tin, and lead.

The process of producing parts with hot chamber die casting machines is relatively fast and uncomplicated due to easy automation. On average, there are 15 cycles per minute – and the molten will be formed into its final shape in as little as 15 to 20 minutes.

The process

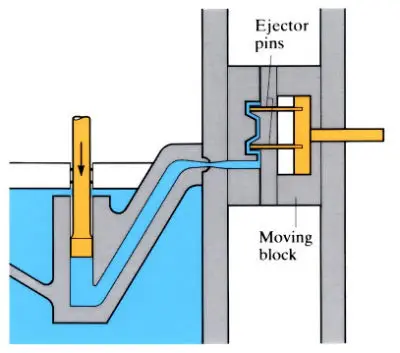

The hot chamber die casting technique is mainly used for metals such as magnesium, zinc, and other low melting alloys.

Compared to the cold chamber die casting process, in this method, the machine itself contains the melting pot, which makes it easier and more efficient.

Source: Open University

The other advantage of the hot chamber process includes long die life and reduced porosity using the alloys, which do not damage or erode the machines when subjected to high temperature and pressure.

Superior quality castings can be manufactured using this process due to the optimal control of molten metal flow to the die.

The furnace is attached to the die casting machine utilizing a metal feed system, most commonly known as a gooseneck. The injection mechanism is immersed within the molten metal.

The power for the injection strokes is provided by the short cylinder located above the molten metal supply.

The plunger rod moves down from the short cylinder to the plunger in contact with the molten metal.

In the starting cycle of casting, the plunger is at the top of the chamber. The molten metal fills the chamber through the intake port.

Once the process begins, the plunger is pushed downwards. The plunger moves downward past the intake ports cutting off the molten metal’s flow to the hot chamber.

Now the chamber has the exact amount of liquid metal that is required to produce the casting. The plunger travels further downwards, forcing the metal within the chamber to the die.

The pressure is held for enough time to solidify the casting. In typical cases, the pressure exerted on the molten metal to manufacture the casting varies from 700psi to 5000psi.

This completes one full cycle of casting.

To prepare for the next cycle of production, the plunger travels in the opposite direction in the hot chamber, opening up the intake ports once again.

Once the intake ports are opened, liquid metal flows into the hot chamber.

Advantages of hot chamber die casting

Hot chamber die casting process’s main advantage is the fast cycle time and the ease of melting the metal directly within the machine.

- Reduced porosity

- Faster cycling production

- Longer life of the machinery (since metals with low melting points are only handled)

- More efficient process

- Lesser metal wastage

Disadvantages of hot-chamber die casting

The main drawback of a high pressure die casting process is porosity. However, this can be reduced by using an evacuated chamber with specialized application techniques.

Since pores are present on the surface, the die casting cannot be fully heat treated as it will lead to the formation of blisters on the metal’s surface.

Another disadvantage is the high initial start-up cost required for setting up the die-casting equipment.

Hot chamber die casting applications

Hot chamber die casting is usually used for metals with a low melting point, such as zinc, tin and lead. Zinc is one of the easier metals to cast and is very economical for small parts. Tin are lead are both commonly used as it is extremely corrosion resistant and offers finished items that have high dimensional accuracy.

Hot chamber die casting is also usually applied for small castings as compared to large castings. Many consumer, commercial and industrial products are manufactured using the hot chamber die casting process including toys, gears, sink faucets and its parts, and connector housings.

Precision die casted items are also widely used in the automobile, aeronautical and construction industry. The article is a part of our comprehensive guide on “Die casting: Process, Equipment, Uses, and More”